- Tel: 0086-21-53021748

- E-mail: export@shdreamax.com

-

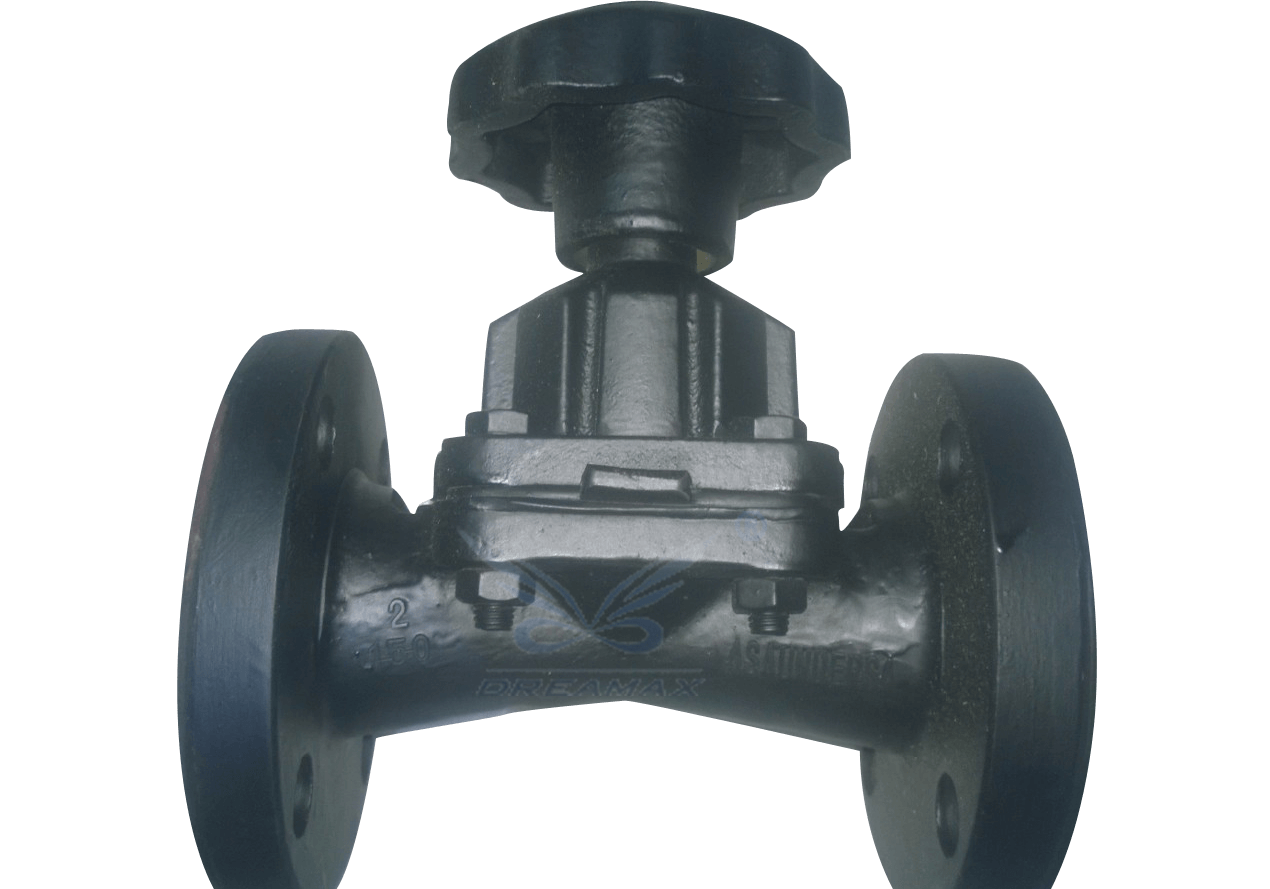

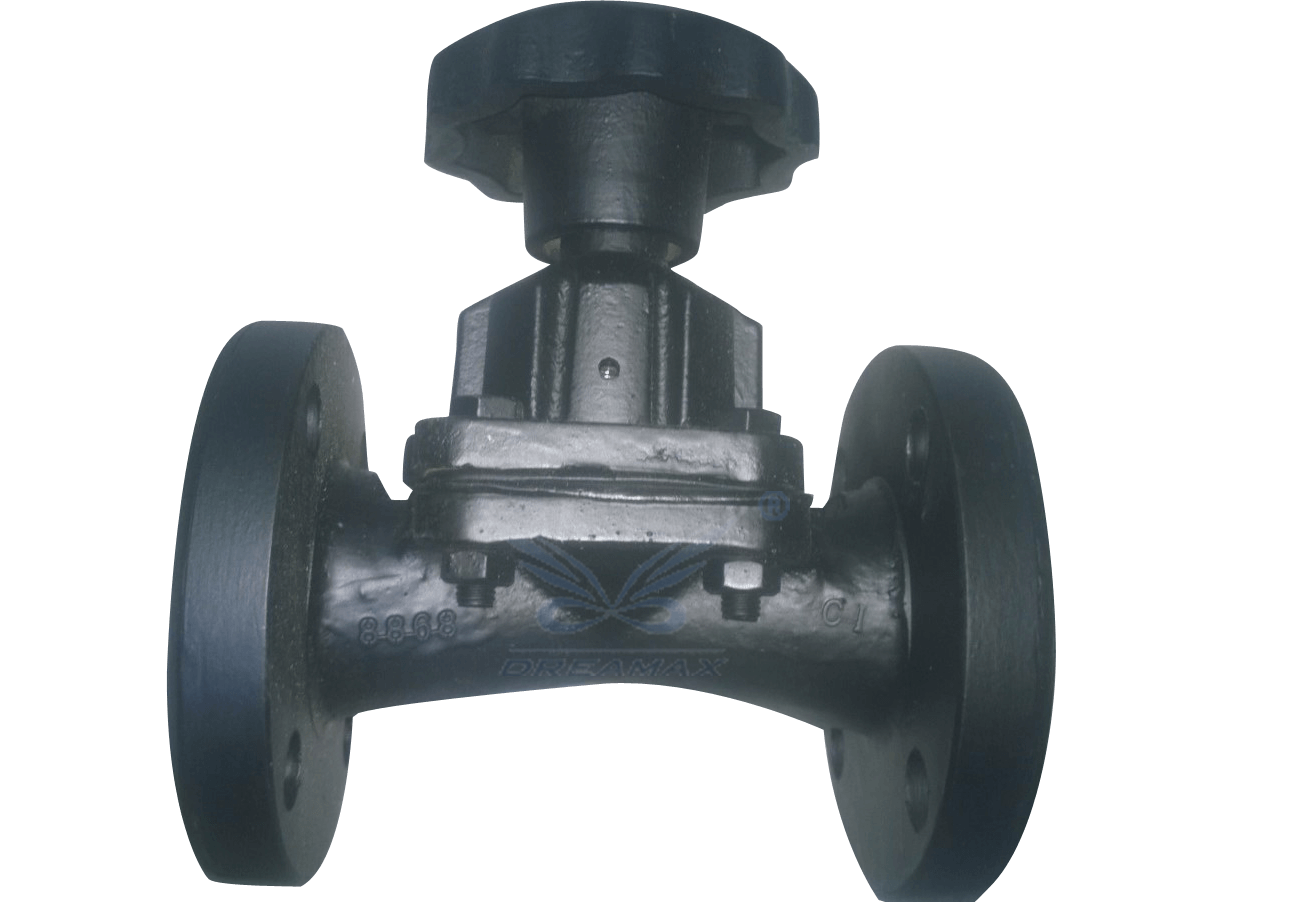

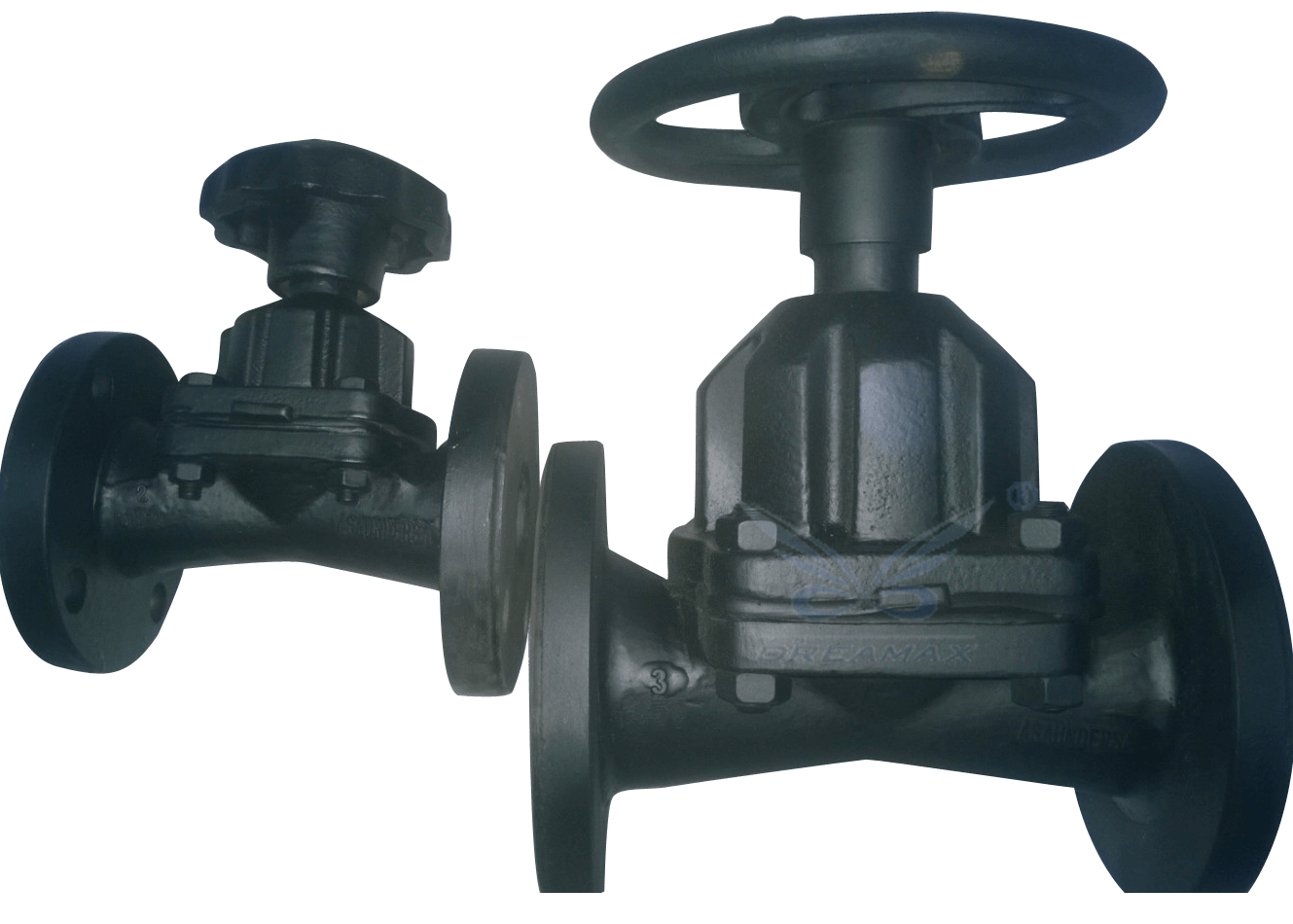

Straight Type Diaphragm Valve

Size range:NPS 1" ~ 12"

Pressure ratings: 150LB

Working temperature: -29℃ ~ +120℃

Suitable Medium: viscose fluid, cellulose fluid, slurry, Sledge and other suspended solids.Water purifying plants, terminal treatment plant, etc..

Body Material:Ductile Iron / A216 WCB

Lining: Ebonite / EPDM / PFA / F46 / F4

Diaphragm Material: Butyl, NBR, EPDM, Viton, and Other material are available according toapplication.

Diaphragm valve generally refers to a valve having a diaphragm of rubber or other flexible material that opens or closes the fluid passage. Diaphragm valves are used on shut-off and throttling service for liquids, slurries and vacuum/gas. The seal is achieved by a flexible membrane, usually elastomer, and possibly reinforced with a metal part. The membrane is tensed by the effect of a stem/compressor with lineal movement until contact is made against the seal of the body. The operating parts of the diaphragm valve are isolated from the flow. This makes this valve suitable for viscous flows and also hazardous, abrasive and corrosive flows as its sealing system avoids any contamination towards or from the environment. Diaphragm valves are available in a wide variety of metals, solid plastics, plastic, rubber and glass linings. They are well suited to the handling of multiple chemical applications both clear fluids as well as slurries. The diaphragm valve has an extended use for applications at low pressures and slurry fluid where most other kinds of valves corrode or become obstructed.

Straight type diaphragm valve

•The fluid passage is straight, which minimizes pressure drop and/or fluid accumulation.

•Applicable to viscose fluid, cellulose fluid, slurry, sledge and other fluids containing suspended solids.

•Used for: Water purifying plants, terminal treatment plant, etc.

2.Consistent Leak-Tightness, even with solids in line

3.Assured purity of Line Fluid, due to the isolation of Valve Mechanism

4.Easy Maintenance

5.Glandless Construction

6.Rising Handwheel

7.Field Serviceable Bonnet Assembly

8.Low Flow Resistance

9.Fluid is isolated from operating mechanism

10.No Stuffing Box

11.Leakage Free

12.Availability of Wide Range of Elastomer Diaphragms

13.Easy to Automate

14.Variable flow direction and installation position

15.Epoxy painting

16.It is a quick opening valve.

2.Face to Face dimension standard as to: MFR-STD

3.Flange dimension conforms as to: ASME B16.5 RF / FF

4.Testing And Inspection as to: API 598

5.Anti Corrosion as per NACE MR-0175 requirement

- Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

- Knife Gate Valves

- Safety Valves

- Steam Traps